I wasted 3 minutes every day on giving my cat food... so I spent 22+ hours designing an automatic cat feeder!

Watch taking the art of over-engineering to a next level… on a cat feeder :)

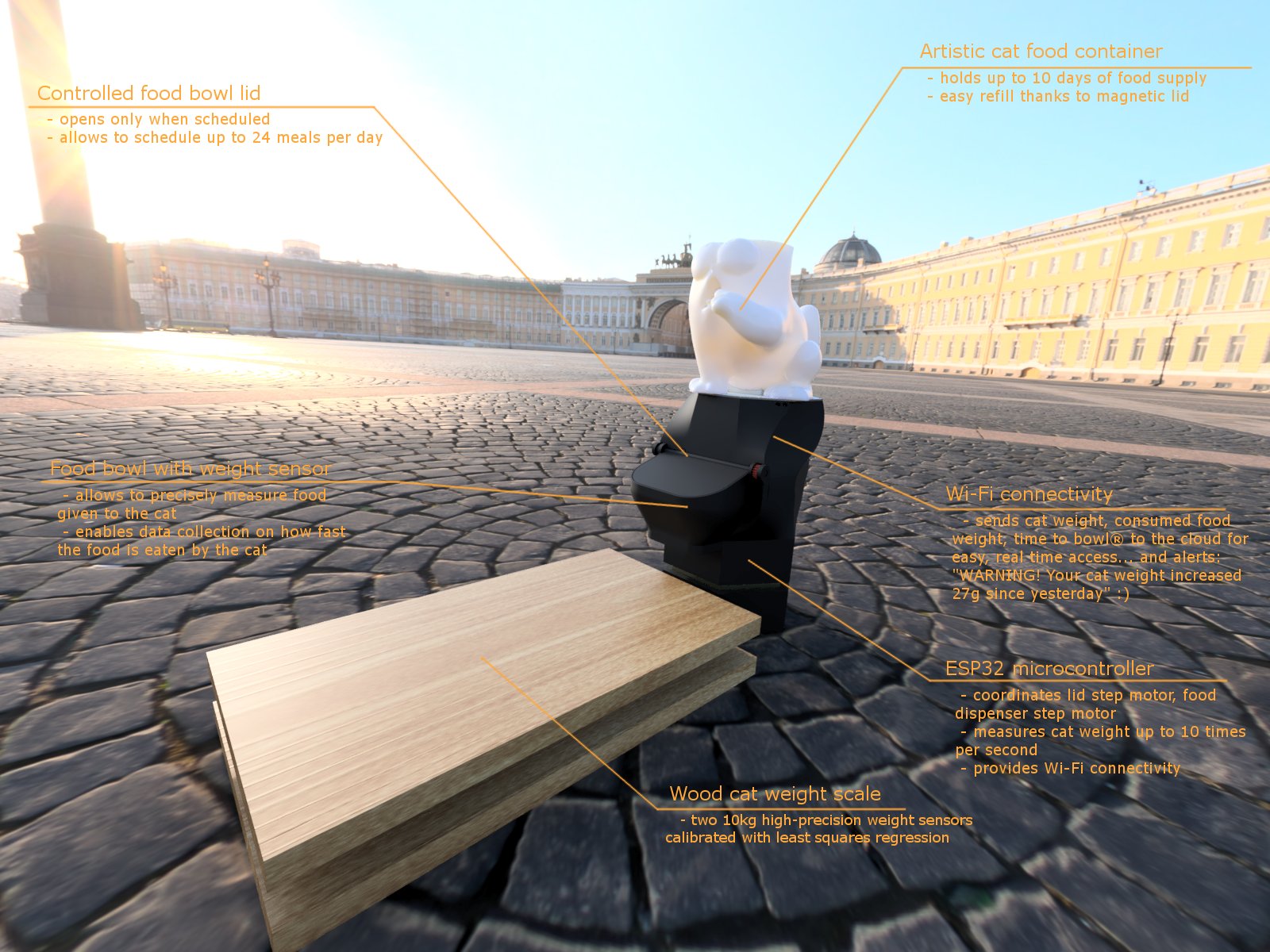

Over-engineering the cat feeder

Just kidding. The time wasn’t obviously the main motivation here. However, my cat, Emma, has tendency, as every other cat, to put on weight. Emma is constantly on a diet and Emma is constantly hungry… Motivation is another topic, however after talking to vet, doing some research, etc, I realized 3 meals per day (morning, midday, evening) is not enough to keep Emma’s stomach constantly busy. I wanted the ultimate, over-engineered cat feeder with all the cool features:

- food given according to defined schedule: cat feeder will make some noise and open at specified times, so the dry food can be eaten

- ability to specify food schedule as needed, and have each meal size easily and precisely adjustable

- measure cat weight

- measure food consumption time

- measure how long does it take the cat to arrive at the cat feeder, from the moment when cat feeder opened

- WiFi connectivity & a website showing a dashboard!

Lets design it & 3D print it

This was my first time doing 3D design, so probably I made every possible mistake along the way. The end result isn’t completely satisfying for me (I was hoping for a better, more organic overall look) and some people say it looks like piano… or a toilet :) Having said that, here is the cat feeder design process in Autodesk Fusion 360. Heads up, it’s 30min long!

Credits: I didn’t model the cat itself, I took it from https://www.thingiverse.com/thing:2985022

Lessons learned

Looking back at the design, and learning some things on the way, I would:

- Design the shell of the cat feeder first. I started from the inside, but I didn’t have any idea how it will look on the outside. The outside look is now basically the result of constraints posed by the mechanical components inside the cat feeder and limits of my 3D printer.

- Use Fusion 360 parameters! I didn’t know they exist… For example, instead of subtracting everywhere 0.2mm as my horizontal 3D printer dimensional accuracy, I would just define it as parameter and use everywhere.

- Make the cat feeder more connected to the wood scale. I predicted the 3D printed part could slide away from wood scale, thus I added two screws between those two components. However, it turned out after printing that the cat feeder is quite tall and the surface between it and the ground isn’t that big, causing the whole construction to be a tad wobbly.

3D printing…

Coming soon!

Eating…

Coming soon!

Please note: the views I express are mine alone and they do not necessarily reflect the views of Amazon.com.